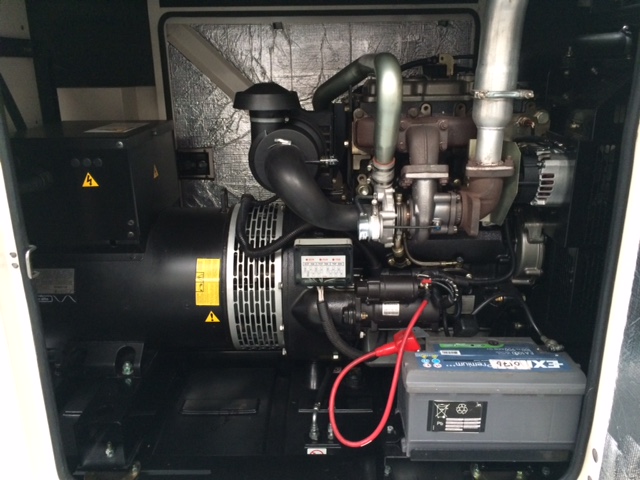

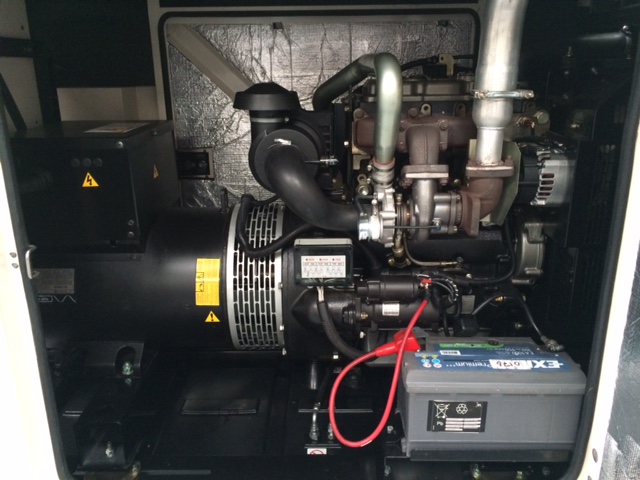

Facility and Operation Managers need to evaluate incident response procedures and plan ahead for regular maintenance of the equipment they are responsible for on site. Backup generator failures happen more often than they need to, often as a result of not having a routine service and maintenance procedure in place.

Regular, proactive servicing and maintenance is obviously the best way to keep your generator in good working order, but an understanding of the following generator issues can reduce your chances of a power failure occurring:-

1. Battery Maintenance

Emergency power systems require batteries that must be assured of starting power. Type, construction, chemistry and classification must meet the specification. Another common cause of battery performance failure is improper adjustment and operation of the battery charger, often with loose or dirty cable connections due to corrosion.

2. Wet Stacking

Diesel engines are designed to operate at a particular temperature. Running a generator for long periods of time at less than optimum temperature can cause the engine to over fuel and leak, potentially causing damage. An annual load bank test can help to prevent such a failure if utilising the building load is not an option.

3. Fuel Contamination

Good fuel quality is critical and often neglected. Fuel can become stagnant, stale, and contain excess water. Sediments can build up in the tank’s bottom risking damage to the generator and contaminating new fuel. Testing and regular fuel polishing as part of scheduled maintenance assures proper operation. In addition, this will minimise waste and reduce your fuel spend.

4. Incorrect Switches and Breakers Position

The generator’s control panel in the Not in Auto or Manual position, a human error! Maintenance routines and periodic off load runs, often neglect to restore the control panel or check that the output breaker is in a proper ready position. Always ensure that the generator’s control panel is in auto and the output breaker (manual) is in the on position.

5. Dirty filters: Air, Fuel and Oil

Emissions’ systems require strict filtration and add the side effect of making generators more susceptible to the environment they are in. Older generators typically suffer with the high additive and low sulphur of today’s diesel fuel adding to the clogging of fuel lines or filters by cleaning out material in the system.

All of the above can be included within a JS Power Service contract or as a standalone service carried out by our engineers. If you are interested in finding out more about any of our generator services, get in touch.