GENERATOR – Ringrose Diesel 40kVA – 415/240v 3 phase/50Hz

BRIEF FROM CUSTOMER

Inspect an old generator at a site in central London and report viability of reinstating.

The generator had stopped working many years before and due to the bad weather over the last few years, there had been problems with waste backing up and flooding cellars at the site during mains power outages.

PROBLEM

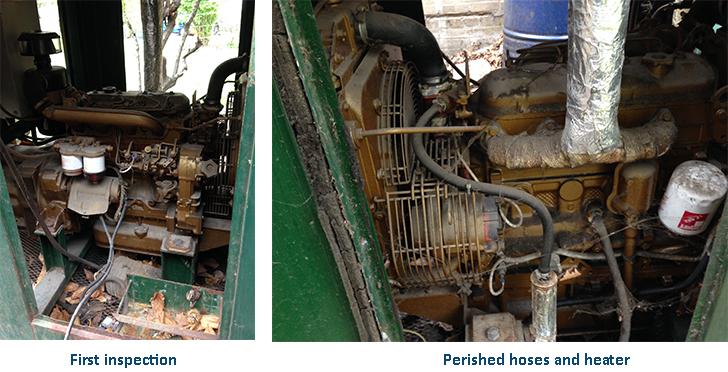

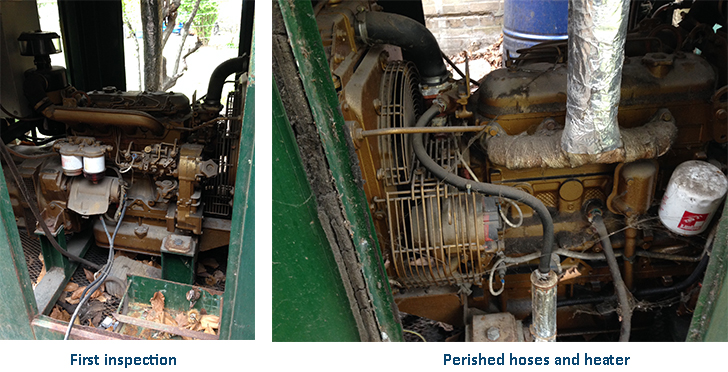

With 9 years of no maintenance, the generator enclosure was full of leaves and debris. The engine and alternator were covered in cob-webs and dust. The radiator cap was found to be missing, along with the battery. The generator control panel was still powered up and being fed from the battery charger output which was still working after all the years offline. The coolant heater was not working, all the coolant heater hoses had solidified and would require changing. There was evidence of oil leaking from blanking plugs on the oil gallery. The fan belt had perished and the radiator matrix was partially blocked with dust and leaves.

SOLUTION

Leaves and debris were removed from the radiator. The old coolant heater and solidified hoses were removed and bypassed using some spare hose. The radiator was then flushed out and refilled with new antifreeze. Fortunately, the radiator cap was found in the debris under the radiator so this was cleaned and refitted. A new battery was fitted and a full JS Power service check was carried out to ascertain whether it was safe to attempt a start. Considering no maintenance had been under-taken, the engine and alternator seemed to be in a reasonable condition so it was considered safe.

The start switch was set to manual and the engine start button was operated. The engine started first turn after 9 years off line.

Note: It is advisable to operate the stop button as soon as practical to ensure you have control of the generator.

The stop button operated correctly.

Another engine start was carried out to check the oil pressure, speed and volts were within acceptable limits. Within minutes of the generator starting, the site maintenance men gathered around in complete awe. They had not believed it was possible for this machine to run again.

The engine was run for a further 10 minutes and all the operating parameters were checked. Oil pressure, water temperature, frequency volts were all within limits. An electrical load was applied by manually switching on the AC pumps from a remote control panel. The load was accepted and the generator ran with no problems. After 10 minutes of load all the operating parameters were recorded for the final inspection report.

The report was compiled and various recommendations were presented to the customer, one of which was a load test which would serve as a means to prove the integrity of the engine and alternator operation under maximum operating conditions.